Solution

Fuda Internet of Things Application in heating

Solution Introduction

With the rapid development of cloud computing, Internet of Things, automatic control and other technologies, people's living standards are constantly improving, and the quality requirements for heating are constantly increasing, and the demand is also increasing. How to ensure the quality of users' heating and how to avoid unnecessary energy waste in high-quality heating.

For this reason, we hope to use the Internet of Things technology to improve the information level of boilers, and ultimately improve the operating efficiency, heating quality, energy-saving effect, fault handling speed and other aspects of the operation, management and maintenance of the boiler system.

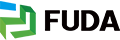

Networking and Description

Fuda's Internet of Things module collects data from the on-site PLC to the VidaGrid secondary development platform through RS232, RS485, network cable and other interfaces. Through the platform visualization drag and drop, the corresponding Web and mobile APP monitoring are generated. At the same time, customers can also use DIACom to achieve remote maintenance of on-site PLC or HMI programs.

Function

Ø Realize remote maintenance of on-site PLC programs

Ø View on-site conditions through the Web or mobile APP, including

n Fault information

n Real-time monitoring of boiler status

n Historical curves of boiler current, voltage, etc. provide energy-saving basis

n Historical curves of boiler temperature, water inlet and outlet, etc.

The main features of the solution are:

(1) The multiple network guarantee mechanism inside the IoT module ensures that the equipment can be quickly restored after an abnormal networking.

(2) Unmanned operation is realized, saving a lot of labor costs.

(3) According to the tracing of on-site curve data, the operating parameters are optimized to improve the operating efficiency of the heat exchange station.

(4) Through real-time analysis of the heat exchange station and fault alarm. The heat exchange station can be remotely diagnosed and located. Rapid response to equipment failure is achieved.

(5) The stable operation of the heat exchange station reduces the failure rate of large-scale heat outages and greatly reduces customer complaints.

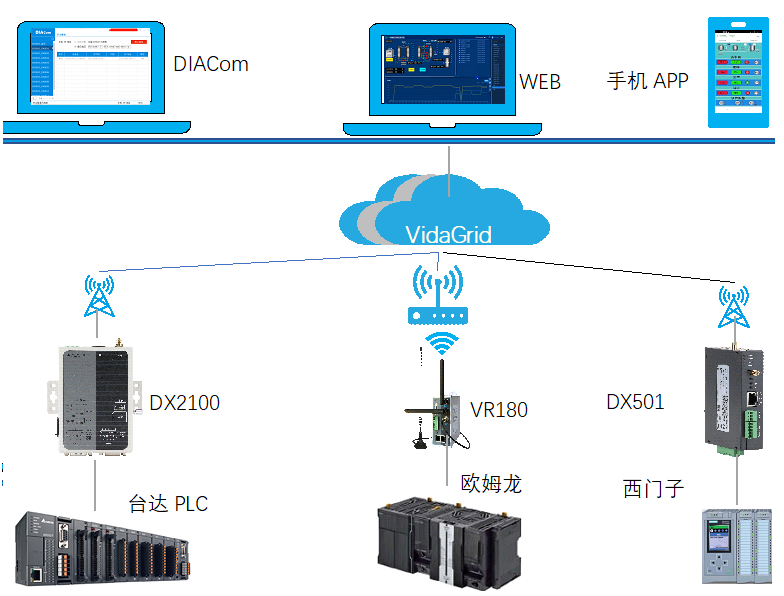

On-site equipment photos:

Secondary development platform screenshot