Solution

Remote monitoring solution for centrifuges

Background

A water plant has multiple centrifuges, and the integration of centrifuges is high. Its troubleshooting is extremely difficult. In addition, the damage of the centrifuge is a process, not a sudden damage. How to improve the life of the centrifuge is a difficult problem.

Therefore, Fuda collects the status of each motor and valve through the Internet of Things module, integrates its information, and can trace the equipment faults and even predict maintenance through information such as running curves.

Solution Overview

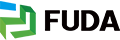

The centrifuge treatment process introduces sewage into the centrifuge through the feed pump, supplemented by flocculants in the medicine tank. The centrifuge separates solids and liquids through high-speed operation. Water is discharged from the drain port, and sludge enters the screw conveyor through the discharge port. The screw conveyor transports the material to the silo. When the centrifuge needs to be cleaned, the centrifuge is cleaned by opening the cleaning valve.

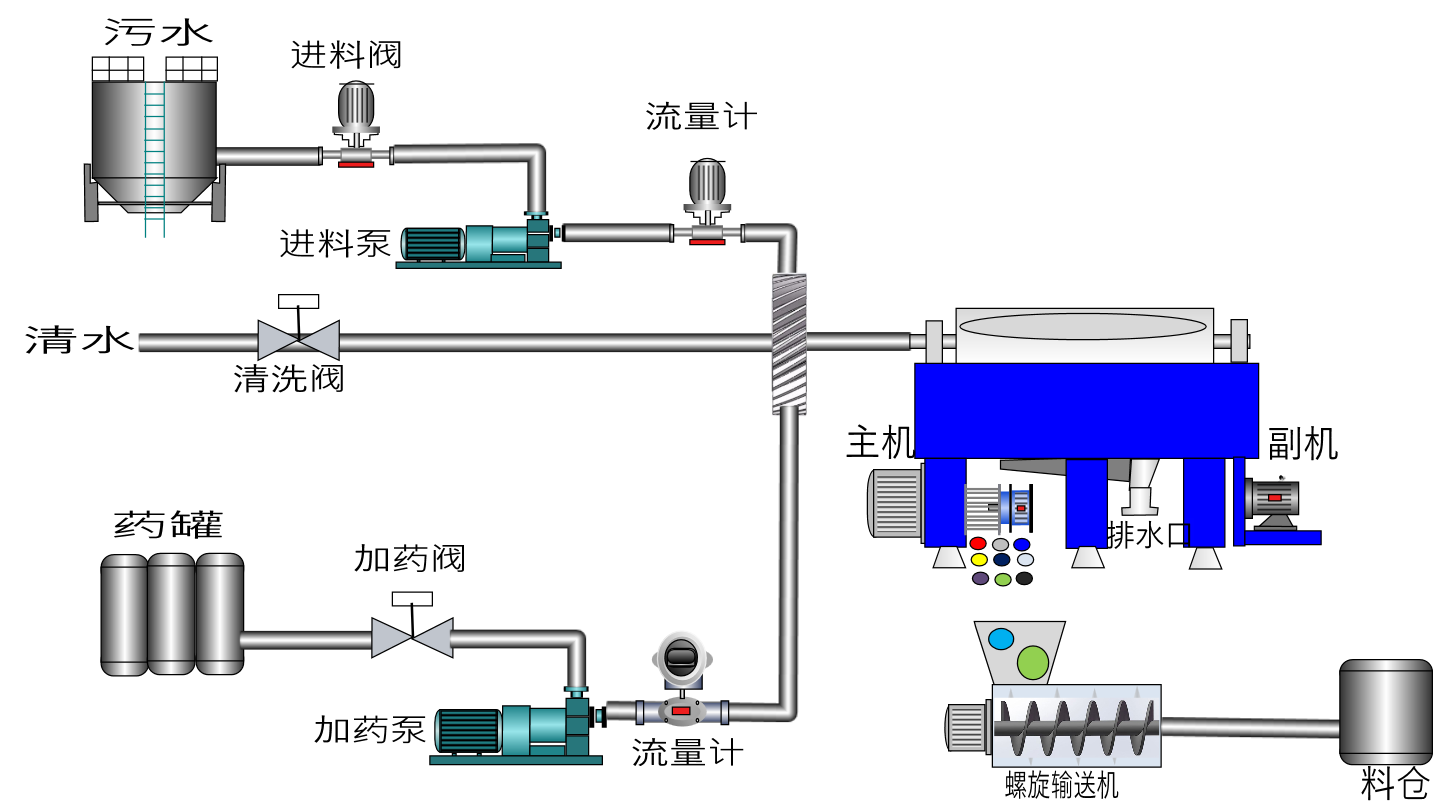

Through the analog input of PLC, the flow information of each pipeline and the temperature information of the main shaft are read. In order to obtain the frequency of the inverter and other information, the frequency is obtained through RS485 communication. HMI collects PLC data through the network port for display. Through digital input, the switch signals such as buttons and valves in place are read. Finally, by installing a switch, VR201 collects PLC information through the network port and transmits it to the cloud.

Main electrical list

Name | Brand | Model | Quantity |

PLC | Delta | AS332T-A | 1 |

PLC Digital input expansion | Delta | AS16AM10N-A | 2 |

PLC Digital output expansion | Delta | AS08AN01R-A | 1 |

PLC Analog input expansion | Delta | AS08AD-B | 3 |

Switch | Delta | DVS005I00 | 1 |

HMI | Delta | DOP-110WS | 1 |

Host inverter30KW | Delta | VFD300C43A | 1 |

Auxiliary machine inverter7.5KW | Delta | VFD73AMS43AFHA | 1 |

Dosing pump inverter1.5KW | Delta | VFD4A2MS43AFHA | 1 |

Conveyor inverter7.5KW | Delta | VFD73AMS43AFHA | 1 |

Feed pump inverter7.5KW | Delta | VFD73AMS43AFHA | 1 |

Remote Module | Fuda | VR201L1 | 1 |

Significance

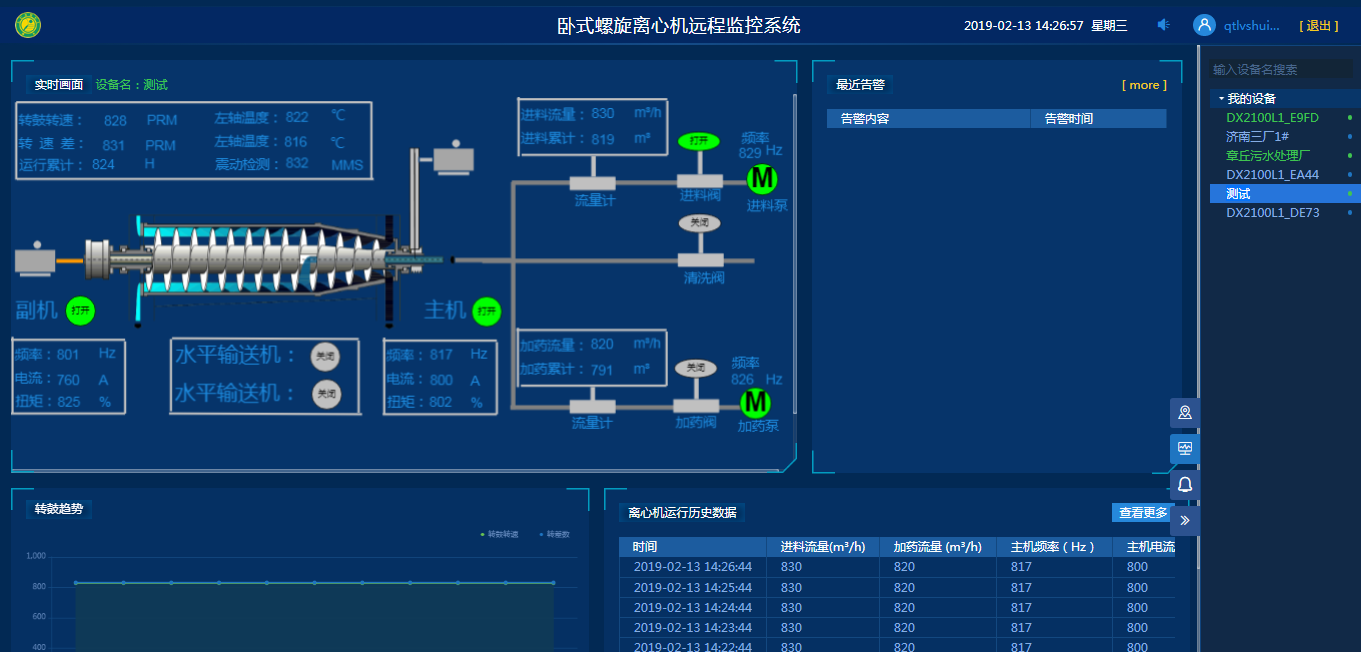

After installing Fuda's IoT module, you don't have to go to the site to check the machine status every time. You can observe the recent status of the machine remotely through the secondary development platform. When there is an early warning, the corresponding person will be notified immediately. It speeds up the resolution of problems and provides guidance for later maintenance precautions.

Partial screenshots of the platform