Solution

Remote monitoring of water supply in water plant by mobile phone APP

Background

Due to the rise of the Internet of Things, the owner of the water plant hopes to use the technology of the Internet of Things to understand the water supply situation of the water plant in real time.

Solution Overview

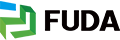

The water plant has a total of 8 local wells and 3 remote wells. There are also two clear water tanks. The process flow is as follows:

Pumps 1# and 2# are 75KW water pumps. In order to ensure the stability of the water outlet pressure, two Delta VFD-750B inverters are configured.

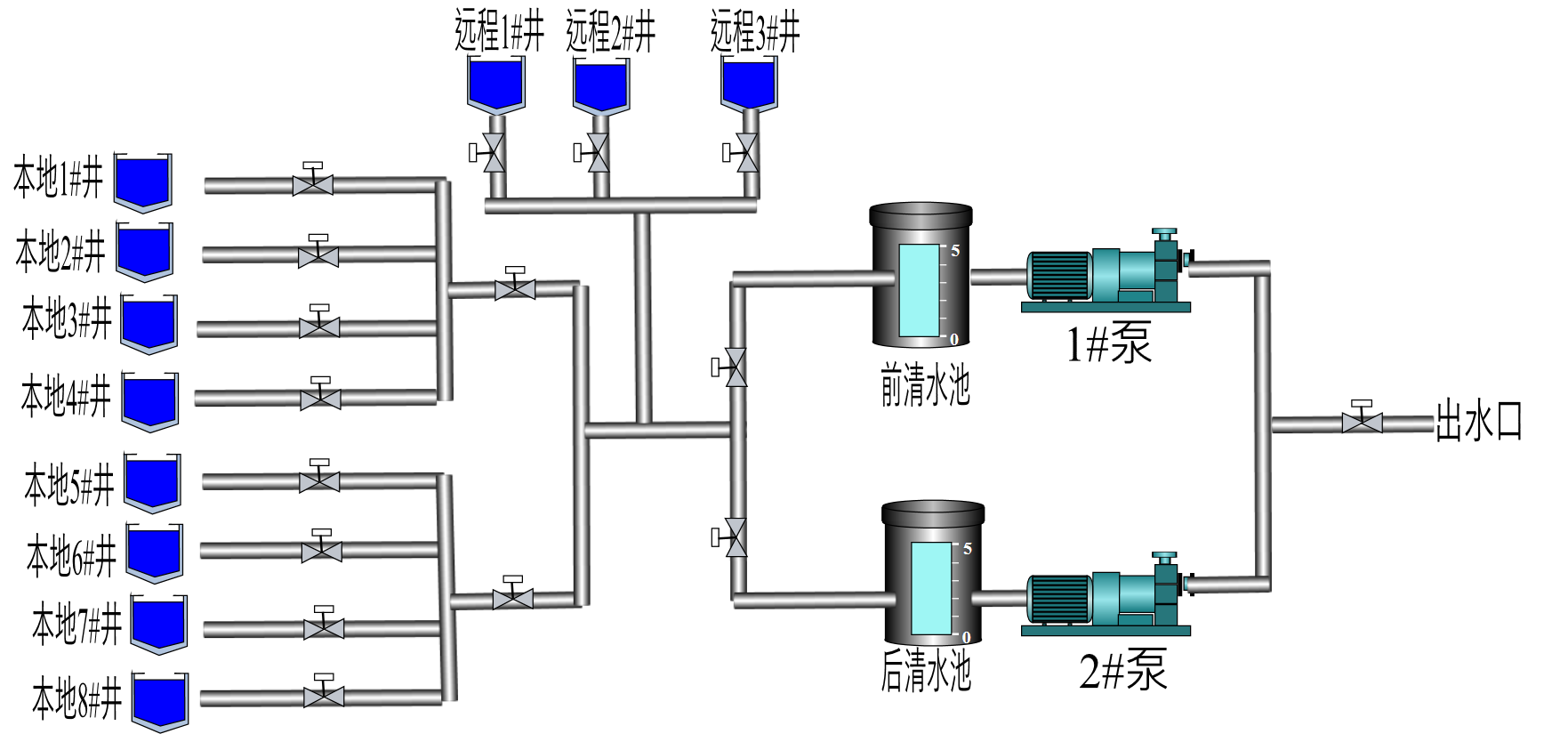

The whole system is divided into three cabinets. Two 75KW inverter cabinets are used to control water pumps. In addition, there is a PLC cabinet, which has a built-in Delta DVP-40ES200R PLC to control the local wells. By adding the analog expansion DVP-04DA-E2, the valve opening of the clear water tank and the rear clear water tank is controlled. PLC1 obtains the data of another PLC and two inverters through the modbus protocol. A Delta DOP-110WS ten-inch touch screen is installed as a local display.

The remote module uses Fuda remote module VR203LN, which collects data from water plant equipment and then transmits it to the cloud via wired. Finally, the secondary development platform is used to drag and drop the configuration to generate a mobile APP monitoring page.

Electrical List

Electrical cabinet | Component name | Brand | Model | Quantity |

PLC cabinet | PLC | Delta | DVP-40ES200R | 1 |

16 digital input expansion | Delta | DVP-16XM211N | 2 | |

4 analog output expansion | Delta | DVP-04DA-E2 | 2 | |

touchscreen | Delta | DOP-110WS | 1 | |

Wired version remote module | Fuda | VR203LN | 1 | |

1#Frequency conversion cabinet | 75kw Frequency Converter | Delta | VFD-750B | 1 |

2#Frequency conversion cabinet | 75kw Frequency Converter | Delta | VFD-750B | 1 |

Monitoring and construction screenshots

The following pictures are screenshots of the on-site installation and the mobile app.