Solution

Remote monitoring system for mobile pumping stations

Background

The daily operation of sewage pumping stations requires a lot of work. The traditional management method of sewage pumping stations is to arrange on-duty personnel at major pumping stations to inspect nearby small pumping stations every day, and dispatch personnel through telephone and pumping station management. However, this method has the disadvantages of large workload, low efficiency and slow response. The traditional management method is increasingly incompatible with the requirements of rapidly developing cities.

With the advancement of science and technology, remote monitoring systems can solve the above-mentioned shortcomings of traditional methods, so they are favored by many companies. Through remote monitoring, real-time collection and rapid concentration of on-site operation data can be achieved, and on-site monitoring data can be obtained, providing a material basis for remote fault diagnosis technology; through remote monitoring, technicians can monitor and control the operating status and various parameters of production systems and on-site equipment without going to the site or harsh environment, so that professionally trained personnel can appear virtually in many monitoring locations, and conveniently use local rich software and hardware resources to perform advanced process control on remote objects to maintain the normal operation of equipment, thereby reducing on-duty staff, and ultimately achieving remote unmanned or less-manned on-duty, achieving the purpose of reducing staff and increasing efficiency.

Solution Overview

Fiber optic cables are deployed to the pump station on site, and VR203 is connected to the network through fiber optic converters to upload the collected data to the cloud. The cloud is then customized according to the definition.

The pump station mainly controls the liquid level. When the water level is high, the water needs to be pumped to other places through a lifting pump. The floating objects in the water are filtered through the screen machine.

The main electrical configuration of some of the stations is as follows:

Qinggu Road Station | |||

Name | Brand | Model | Quantity |

PLC | Delta | AS332T-A | 1 |

Digital input | Delta | AS16AM10N-A | 1 |

Digital output | Delta | AS08AN01R-A | 1 |

Analog input | Delta | AS08AD-B | 1 |

Switch | Delta | DVS005I00 | 1 |

Remote Module | Fuda | VR230LN | 1 |

Weisan Road Station | |||

Name | Brand | Model | Quantity |

PLC | Delta | AS332T-A | 1 |

Digital input | Delta | AS16AM10N-A | 3 |

Digital output | Delta | AS08AN01R-A | 1 |

Analog input | Delta | AS08AD-B | 5 |

Switch | Delta | DVS005I00 | 1 |

Remote Module | Fuda | VR230LN | 1 |

Significance

Realize unattended operation and ensure stable operation of equipment through inspection. Timely alarm system can notify relevant persons in charge at the first time. Realize stable, efficient and economical operation of pump station.

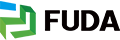

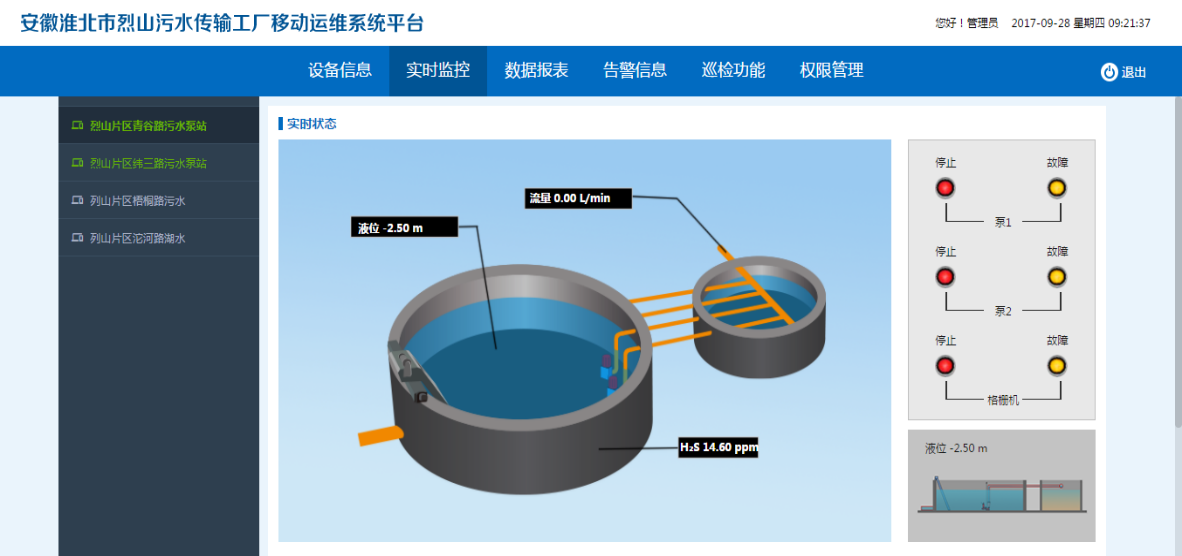

Some screenshots of the implementation

Website screenshot 1

Website screenshot 2

现场施工照片On-site construction photos

HMI photo